|

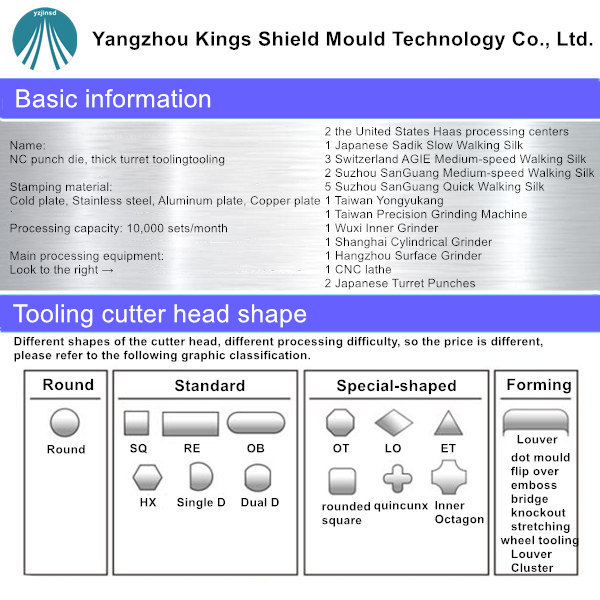

Yangzhou Kings Shield Mould Technology Co., Ltd.

|

Amada punch tool Amada round tool Square tool

| Price: | 100.0 USD |

| Payment Terms: | T/T,WU,Paypal |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Material: Punch M35, Die SKD11

Heat treatment:HRC 60°- 62°

Option: Coating with TiCN or TiN

Packaging Details: Wooden Case, Carton

2-15 days send

Amada Punch Tool Amada Standard Shape Tool Round Tool Square Tool

Function Description:

1. spring retainer adopt two sides taper design, both sides can be used, extended grinding.

2. hq punch is special high-speed steel, add the alloy composition, punch life longer.

3. increased the die cutting edge thickness in 2mm, strength increased in punching thickness sheet, extended grinding capacity.

4. no slug die design as cutting edge concave emboss, eliminate slug pulling, jumping materials and floating.

5. guide self-lubricating design, graphite processing, to reduce the abrasion of punch turret hole, to increase the service life of punch and tools.

| Why choose us Yangzhou Kings Shield Mould Technology Co., Ltd. (yzjinsd) | |||||

| Why us yzjinsd? 1. Punching data Punching SPCC T=1.5mm with standard B station 5x30 (material varies according to machine accuracy) | |||||

| Material | Number of first grinding and punching | Number of secondary grinding and punching | Grinding capacity each time(mm) | Grinding times | The Life of a Punch Core |

| SLD | 250,000 | 237,500 | 0.2 | 10 | 2,200,000 |

| SKH51 | 820,000 | 779,000 | 0.2 | 10 | 7,500,000 |

| SKH51+TiCN | 1,030,000 | 950,000 | 0.2 | 10 | 9,000,000 |

| Actual case 1. Electrical cabinet manufacturer, Amada machine punching T=2.0mm stainless steel with yzjinsd 5x30 rectangular die, the number of first grinding and punching is 92,000 times. 2. Kitchen Equipment Manufacturing Company, Jiangsu JIN FANG YUAN JFY CNC punching machine. Punching T=1.5mm stainless steel SUS with D6x25 die, the number of first grinding and punching is 650,000 times. 3. Chemical Equipment Company, Yawei machine, punching T=3.7mm stainless steel SUS201 with D20 die, the number of first grinding and punching is 50,000 time. | |||||

| Why us yzjinsd? 2. Punching times after grinding Do you have the feeling that the life of some other international die companies is very good at the first punching, but the second and third life of the die after the cutting edge decreases quickly? Why? The hardened layer is not deep enough, the structure is not fine enough, and the toughness is not the best. Our moulds are different. The first time is good, and the second and third times are also good. Our dies are very durable. The hardened layer on the edge of the dies we processed has fine structure and high toughness. | |||||

Ordering instructions:

1. CNC punch brand? and model?

2. CNC punching die station structure

3. Types of needs

thick turret 85/thick turret 90/thick turret quick adjust/thick turret heavy duty

forming mould/Murata/Trumpf/Euromac/Finn-power/machine tool accessories

4. Stamping sheet

material and thickness / Lower die clearance

5. Ordered parts

complete set / punch / lower die / backplane / etc.

6. Cutter head shape and size

ROUND / RE / SQ / SD single D /WD dual-D / HX / OT / QD / ET / LO / OB / LD long D /other

For example:

AMADA CNCN punch

2510NT

ABCDE

thick turret 85

stainless steel 2mm

complete set

A-SQ5

Thank you for your visiting.